Maintaining a clean and hygienic environment in commercial kitchens is crucial for ensuring food safety and passing health inspections. One of the most challenging pieces of equipment to keep clean is the commercial fryer, yet it plays an essential role in many restaurant operations. Regular cleaning practices not only make health inspections easier but also contribute to the longevity and efficiency of fryers, ultimately benefiting both business owners and customers.

Commercial fryers are used extensively in various food establishments, from fast-food joints to high-end restaurants. They facilitate quick cooking times and deliver consistent results, making them indispensable in many kitchens. However, due to their frequent use, they can quickly accumulate grease and food particles, becoming potential breeding grounds for bacteria if not cleaned regularly. This accumulation poses a risk not only to food safety but also increases the likelihood of equipment malfunction or even fire hazards.

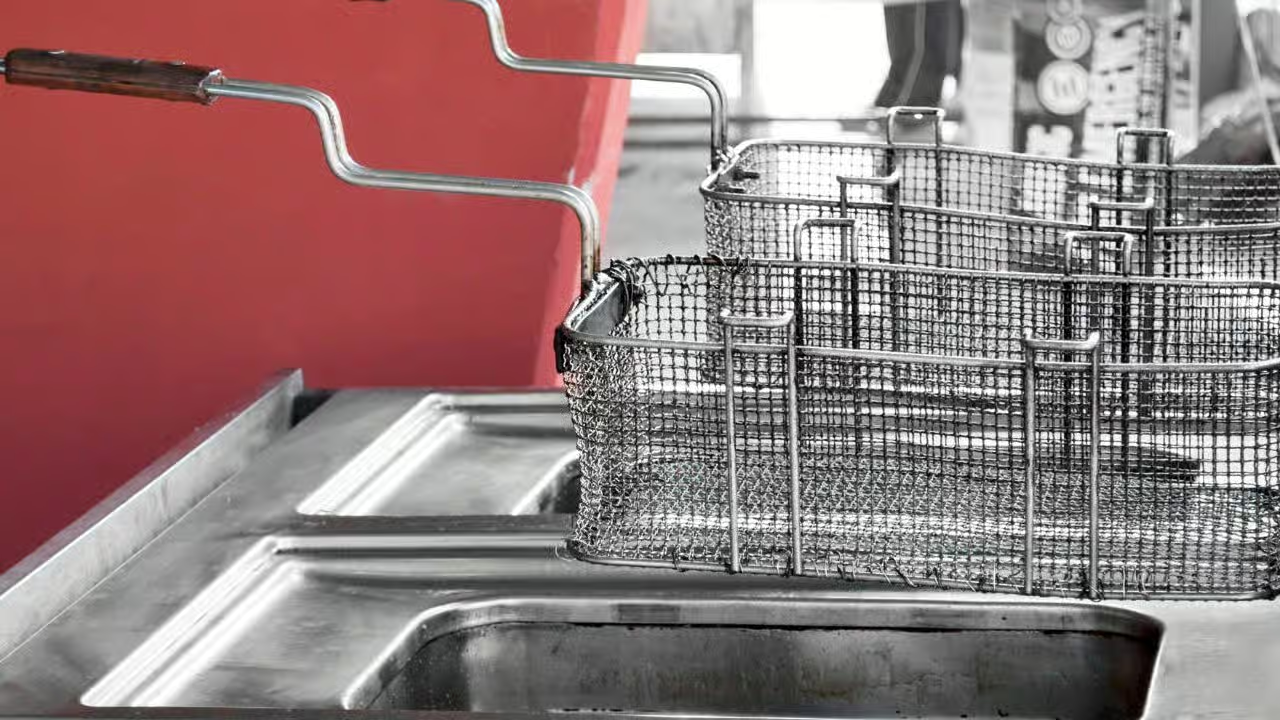

Implementing regular Cleaning commercial fryer fryers helps mitigate these risks significantly. By establishing a daily regimen that includes draining old oil, scraping off carbon deposits, and wiping down surfaces with appropriate cleaning agents, kitchen staff can ensure that fryers remain in optimal condition. Additionally, scheduling more thorough weekly deep cleans—where components like baskets and heating elements are soaked or scrubbed—further ensures that all parts are free from harmful residues.

These routine practices simplify the process when it comes time for health inspections. Inspectors typically look for cleanliness standards as part of their evaluation criteria; thus, consistently maintaining clean equipment reflects positively on an establishment’s commitment to hygiene standards. A well-maintained fryer demonstrates proactive management efforts toward preventing contamination issues before they arise.

Moreover, regular cleaning extends beyond merely passing inspections—it enhances operational efficiency too. Clean fryers heat oil more evenly and maintain temperature better than neglected ones do; this leads directly to improved cooking performance which translates into higher quality dishes being served promptly without compromising taste or texture due either overcooked/undercooked foods caused by uneven temperatures within dirty machines themselves!

Furthermore investing time/resources into keeping appliances tidy reduces long-term costs associated needing replace damaged parts prematurely due neglect-related wear tear! In conclusion adopting disciplined approach towards upkeep vital piece culinary infrastructure offers multitude benefits ranging smoother inspection processes enhanced customer satisfaction increased profitability overall success venture itself!